Why work with GD?

We don’t shy away from problems. Since 1973, our engineers have tackled the toughest challenges for the most rigorous environments, from the battlefield to the factory floor—and anywhere in between.

Industries

Over the decades, our team of hardware, software, and embedded systems engineers have solved thousands of problems in safety- and mission-critical industries:

Products

- Interactive Product Sampler

PRODUCTS

PRODUCTSInteractive Product Sampler

ExploreBrowse our range of American-made workstations, displays systems, and other ruggedized electronics.

- Rugged Displays

PRODUCTS

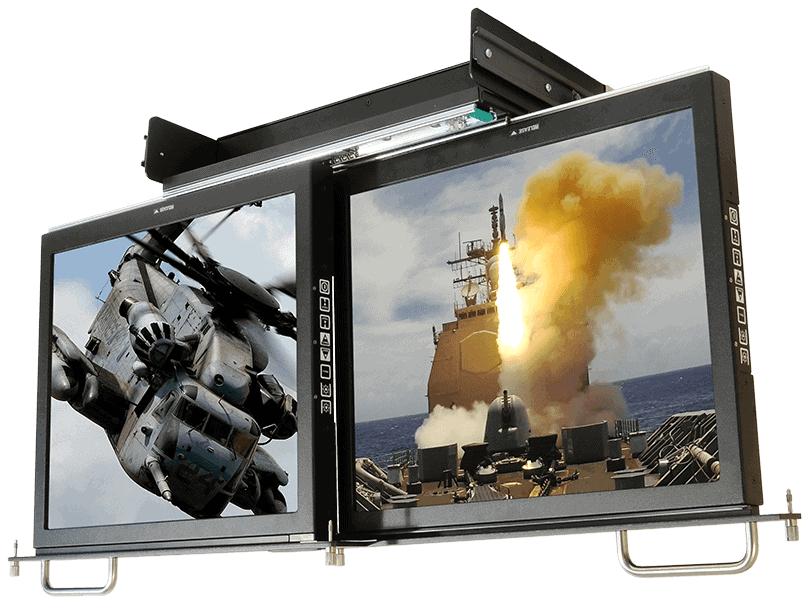

PRODUCTSRugged Displays

Learn MorePanel mount, rack mount, and standalone display solutions built to withstand the harshest environments from the factory floor to the battlefield.

- Keyboards

PRODUCTS

PRODUCTSKeyboards

Learn MoreMilitary- and industrial-grade highly-customizable keyboards, including a variety of pointing devices, backlight colors, enclosures, interfaces, and more.

- Power Supplies

PRODUCTS

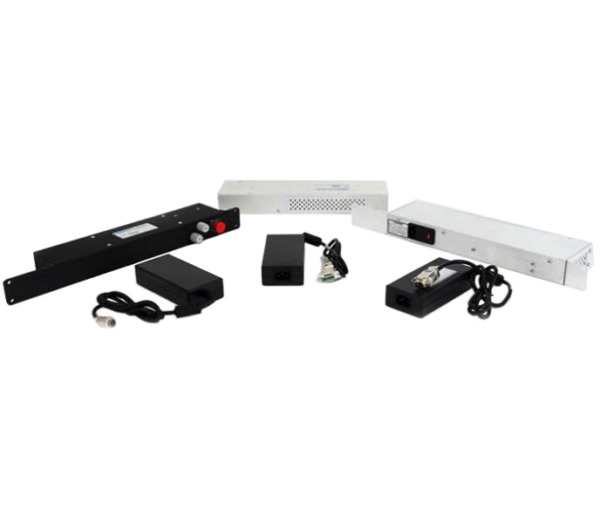

PRODUCTSPower Supplies

Learn MoreRugged power supplies for extreme environments, including wide operating temperature ranges, shock and vibration protection, and EMI compliance to military standards

- Options & Accessories

PRODUCTS

PRODUCTSOptions & Accessories

Learn MoreFrom video cables and touch screens to KVM switches and mounting arms, learn more about our complimentary options to ensure your display functions at peak performance.

- Display Enhancement Services

PRODUCTS

PRODUCTSDisplay Enhancement Services

Learn MoreBrightness and NVIS enhancements, heaters, increased resistance to shock, vibration and moisture, and more to adapt your display to its environment.

- Commercial-grade Displays

PRODUCTS

PRODUCTSCommercial-grade Displays

Learn MoreQuality, durable display systems for tough applications including outdoor signage and light-industrial environments

Services

- Independent Verification & Validation (IV&V)

services

servicesIndependent Verification & Validation (IV&V)

Learn MoreUnit, Integration, and Systems testing for certified environments (DO-178, FDA, etc.) and other safety-critical applications

- Safety-Critical Software Development

services

servicesSafety-Critical Software Development

Learn MoreFull Software Development Life Cycle solutions from planning to design to certification and post-launch.

- Application Development

services

servicesApplication Development

Learn MoreCustomized application development for safety- and business-critical platforms, including Windows, Mac, Linux, iOS, Android, and RTOS.

- Agency Compliance & Certification

services

servicesAgency Compliance & Certification

Learn MoreWork with industry experts on the planning and execution of your product’s regulatory submission.

- Product Evaluation & Modification

services

servicesProduct Evaluation & Modification

Learn MoreRetrofit legacy equipment to be integrated with new or updated systems.