Since 1973, General Digital Corporation has provided innovative design, development, and manufacturing solutions to the toughest of engineering challenges. Despite the numerous engineering companies that have come and gone in the last 50 years, General Digital’s dedication to quality American engineering has stood the test of time—from our VuePoint terminals released in the 1970s as one of the first available industrial touch screens, to our Tactical TwoView, a ruggedized MIL-certified workstation that was one of the first military-grade products to utilize USB-C. Our experienced electrical, mechanical, optical, and quality-control engineers (coupled with the power of our 50,000 sq. ft. manufacturing facility) allow us to tackle nearly any requirement.

Electrical Engineering

Engineering expertise includes:

- Analog and digital schematic and printed circuit board design using ORCAD software with PSPICE and error mode simulation

- LED backlight design

- Sunlight / daylight readable

- NVIS displays

- CCFL replacement

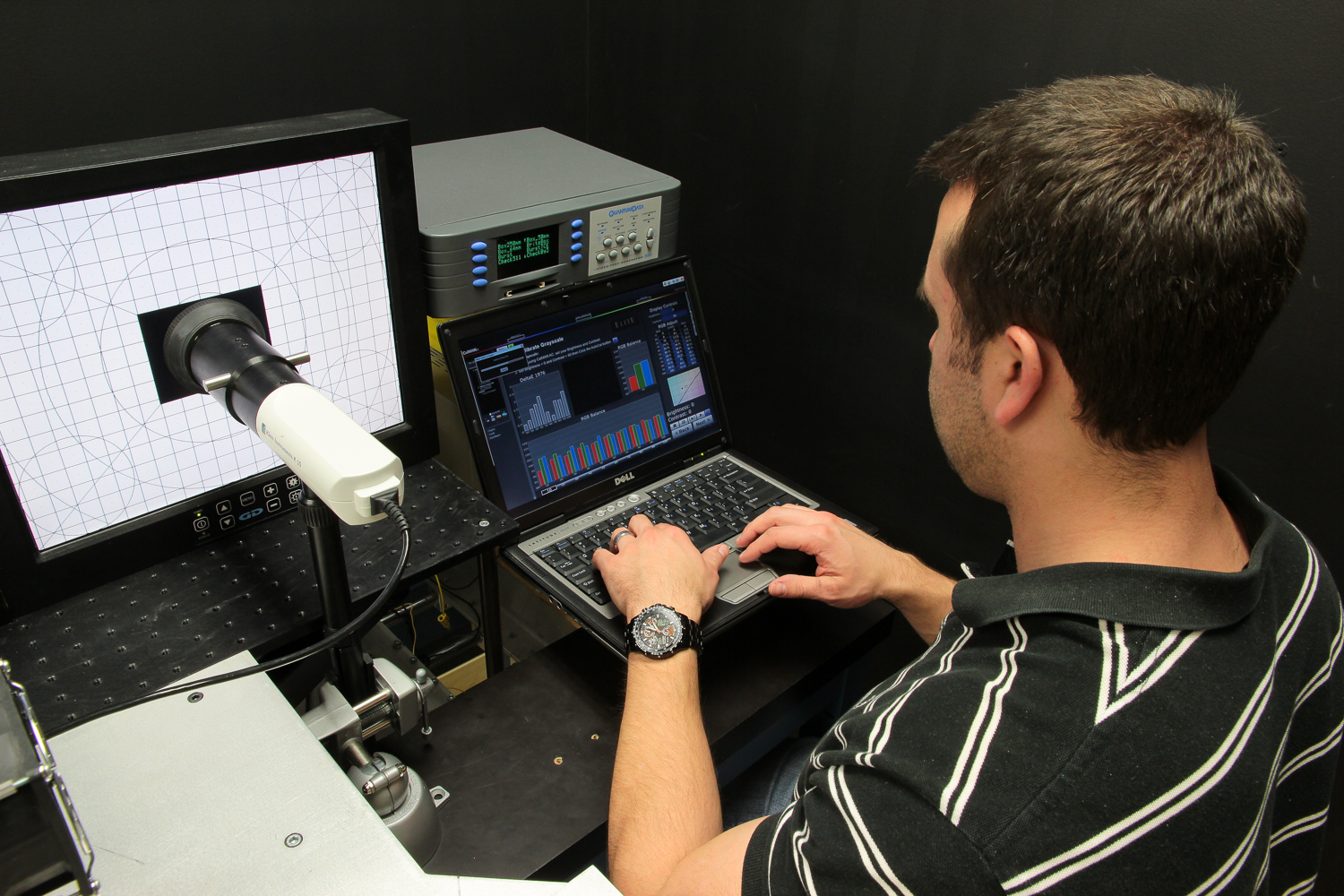

- Video compatibility verification and custom signal creation and matching using Quantum Data QD701A and 881D programmable video generators

- Digital oscilloscopes up to 1GHz

- Logic and digital communication protocol analyzers

- Systems Engineering

- Power Management Design

General Digital also has the following in-house production equipment to build and test circuit boards:

- High-speed CNC, PCB stuffing, automated Pick-and-Place base machine and feeders (DDM Novastar LE40V)

- Capable of 13.5″ x 18″ palletized boards for rapid assembly

- Reflow Oven (DDM Novastar GF-120HC-HT)

- 41″ 3-stage programmable profile solder reflow tunnel capable of 10 board-inches per minute for high throughput

- Pre- and post-production PCB qualification capability

- Stencil Printer (DDM Novastar SPR-25)

- Ultrasonic Cleaner (Branson 8510MTH)

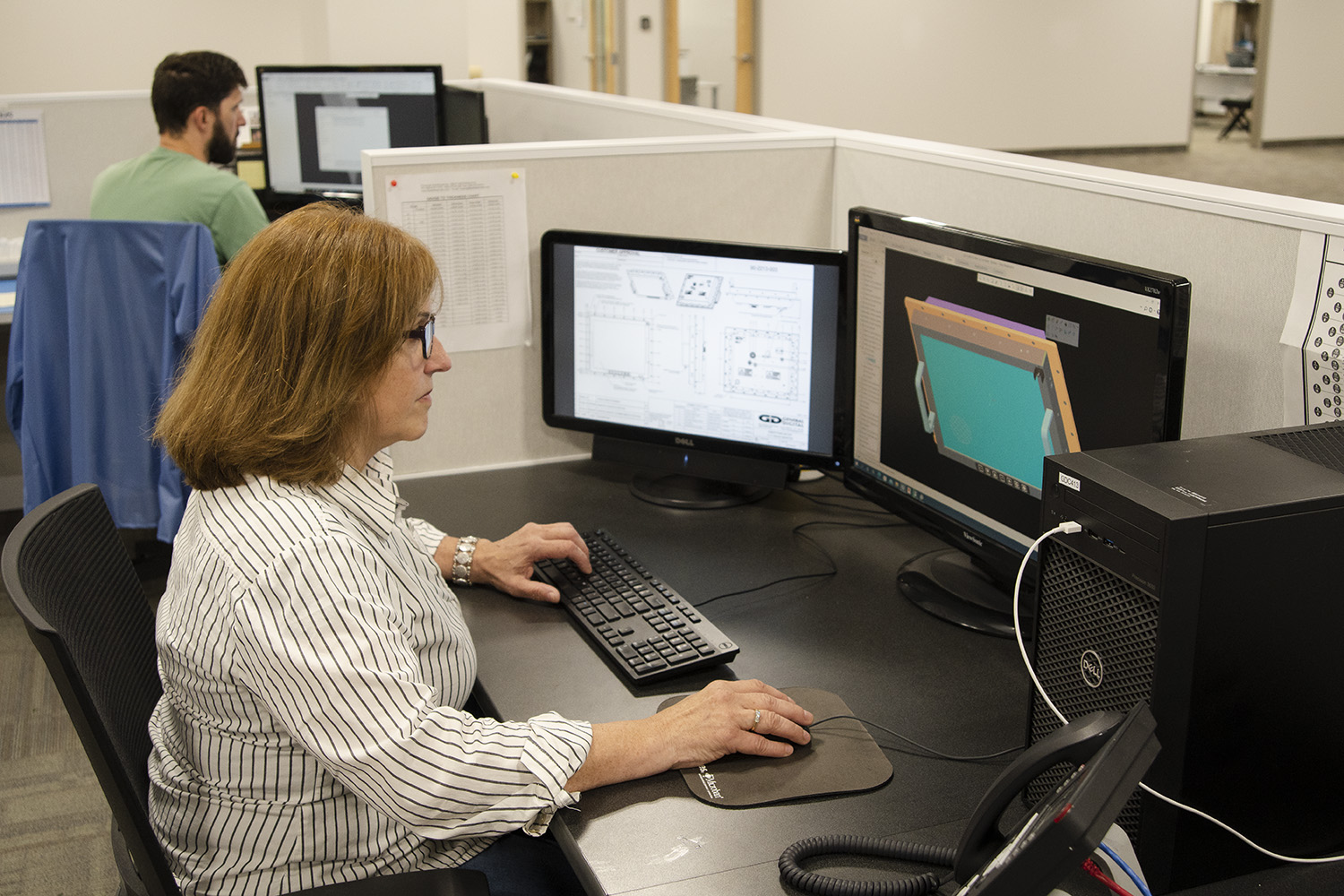

Mechanical Engineering

Design expertise includes:

- 3D/CAD design using state-of-the-art Pro-Engineer Creo software

- Thermal analysis using FloEFD software by Mentor Graphics

- Specialize in designing stationary and sliding rack mount equipment for commercial, industrial and military applications

- Design of products compliant to customer-specific requirements—such as brackets, bezels, and enclosures—for commercial, industrial, marine, aerospace and military marketplaces

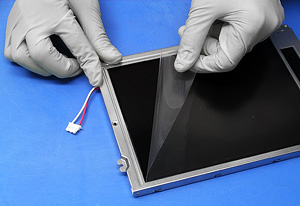

Optical/Display Engineering + Enhancement

Touch screens, vandal shields, polarizers and optical films are just some of the many options our Optical Bonding Laboratories utilize to provide the latest and most effective display enhancements.

- Selection and integration of the following optical / display enhancements:

- Surface laminations of optical, first-surface, films (antireflective, antiglare, AR/AG, privacy, ITO, etc.)

- Automated lamination (displays up to 22″ diag) using Sun-Tec TMS-SA-2

- Manual lamination for larger display sizes

Specialty reflective, prismatic and polarizing films behind the LCD

Specialty reflective, prismatic and polarizing films behind the LCD- Touch screens

- Vandal shields (Gorilla Glass®, shatterproof glass, optically bonded vandal shields, plastics)

- EMI / RFI (ITO, mesh, etc.) filters

- Optical and membrane heaters

- LED backlights (sunlight / daylight or CCFL replacement)

- NVIS filters

- ¼-wave retarders and circular polarizers

- Surface laminations of optical, first-surface, films (antireflective, antiglare, AR/AG, privacy, ITO, etc.)

- All display disassembly, integration and reassembly performed in a Class 10 clean room or Class 100 laminar flow bench using ion showers and guns

- Optical laboratory services in-house

Quality Control

Our reputation is built on the products and services we provide. For this reason, quality control inspection is performed on 100% of products we manufacture, not just on a sample lot.

Display Systems Products

- 168-hour room temperature (or equivalent) burn-in of military and avionic products

- 72-hour room temperature (or equivalent) burn-in of commercial and industrial products

- 100% of products visually and functionally inspected

- Shop Traveler records maintained for 20 years (minimum), and includes:

- Serial numbers of all electrical subassemblies [LCD, controllers (PCBs), power supply, etc.]

- Acceptance test plans

- Inspection results (with QC signatures to track responsible parties)

- AS9100D and ISO 9001:2015 Quality Management System Certified (view certificate)

- Inspectors are trained and certified to:

- IPC-A-610

- IPC-7711

- IPC-7721

- IPC/WHMA-A-620-C

- J-STD-001

- Quality Manual (view manual)

- LCD Overlays inspected using Scratch-Dig limit of 80-50 as defined in MIL-PRF-13830B

- Certificate of Conformance (C of C) available upon request

- Inspection equipment includes:

- Magnification loupes and reticule

- OEM display quality requirements

Optical Bonding Laboratories Products/Services

- Displays (consigned or purchased) are visually and functionally inspected before disassembly for optical bonding to optimize bonding yields. Inspection size/percentage determined by customer/quotation

- Video test kits are created and stored in OBL inventory

- LCD overlays are visually inspected before optical bonding to maximize optical bonding yields

- 100% visual and functional of display assembly after optical bonding

- Acceptance test procedures

- Shop Traveler records maintained for 20 years (minimum), and includes:

- Serial numbers of all electrical subassemblies [LCD, controllers (PCBs), power supply, etc.]

- Acceptance test plans

- Inspection results (with QC signatures to track responsible parties)

- Quality Manual

- Inspection equipment includes:

- Magnification loupes and reticule

- OEM display quality requirements

- Inspection equipment includes: