Vision without action is merely a dream. Action without vision just passes the time. Vision with action can change the world.

-Joel Barker

You have an idea for a product that could potentially change the world.

Congratulations!

Not to be harsh, but people come up with good ideas all the time. Most of them stay just that—an idea.

Don’t get me wrong, ideas are fantastic. But…they can’t change the world without the long-term vision to transform them into a reality.

Below are six incredibly easy but often overlooked steps to bring a safety-critical product to market successfully.

1) Your road map comes first

You’re a product manager at a medical device company. Someone came to you with a great idea and says that we have to bring this to market by the end of the year. It could change the world, it’s such a good idea! People need to know about it!

You put together an amazing PowerPoint, fudge some projections, and raise some capital from investors. You start building your product, quickly, and you get a working prototype within twelve months.

Dang, you’re good!

Now all that’s left is to check that box called “FDA Certification.” No problem, this product is incredible. No doubt they’ll fast track it for us, right?

Sorry, but the world doesn’t work that way. The FDA rejects your submission. You didn’t document everything properly. You didn’t get your product independently verified and validated. There’s some bad code in there and your product fails .01% of the time, which is unacceptable for a medical device.

You set out with the intention of building your product, not taking your product to market.

Those investors are demanding returns, and you have nothing to give them. You need to raise even more capital because now you have to start completely from scratch. In your hurry to change the world, you:

- Delayed your product launch by years

- Devalued your company

- Diluted your equity

- Wasted hundreds of thousands, if not millions, of dollars

All of this could have been avoided if you had laid out a road map from the beginning.

Before you start ANY work on your project, you need to set realistic milestones and plan every step in the process.

- Lay out a clear intended use for your product

- Outline what certifications you need to obtain (and how you will test to them)

- Let your engineering team figure out how to achieve that intended use in a way that is compliant and cost-effective

There’s an old adage, an hour of planning saves a hundred hours of execution. Spending a little extra time and money planning your roadmap will save you countless headaches down the line.

2) Set realistic financial expectations

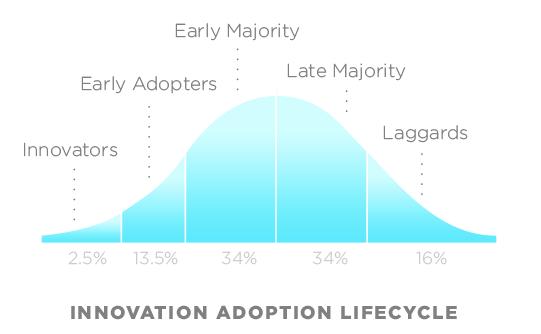

You might think that the minute your product hits the market, sales will go through the roof. In reality, it often takes years for new companies or new products to reach profitability as the market adoption rate increases.

Part of your roadmap is going to be projecting how much you need to invest (and when) and how long it will take to bring your product to market.

You don’t have to do everything all at once. It might sound like a good idea to take five years developing what you think is the absolute best possible version of your product. However, in those five years, you’ve sunk millions into R&D. While you were tinkering and perfecting, the market need has already been addressed by a competitor.

Instead, think about what are the most urgent needs that your product needs to address. What can you build for a first-generation product that you can take to market reasonably quickly? By doing a phased approach, profits from your first generations can fund future improvements. This will mitigate the need for investment early on, allowing you to retain more equity while preventing your company from becoming over-leveraged.

3) Know your role

Executives are executives. Their job is to lay out a vision for their company, to plan a road map, make financial projections, and define an intended use for a product. Big picture stuff.

Executives are (usually) not engineers. The same way you wouldn’t throw your junior software developer in front of a board of directors to explain your product road map, your executives shouldn’t be micromanaging your engineers telling them how they want the product built.

This might sound controversial, but it shouldn’t.

It is not the executive’s job to tell an engineer how to achieve the product’s intended use. Engineers need the flexibility to find the best option available.

4) Document Everything

When you’re building safety-critical products in certified environments such as medical devices, aviation equipment, or autonomous vehicles, the certifications you have to meet are incredibly strict.

As they should be. If a plane’s flight control system fails, that’s a very bad thing. The 737 MAX tragedies are a harrowing example of this.

When your product submission is being reviewed, you’re going to need to document that you’ve proven that every single function, every single line of code, does exactly what you intend it to do and nothing else.

5) Know What You Don’t Know

When being interviewed by Academy Award winning filmmaker Errol Morris for the 2013 documentary The Unknown Known, former Defense Secretary Donald Rumsfeld outlined four different types of knowledge:

- There are known knowns, which are things you know that you know. For example, I know that 2+2=4.

- There are known unknowns, which are things that you know that you don’t know. I know that I do not know how to build an F-15.

- There are unknown unknowns, which are things that you don’t know that you don’t know. Like aliens.

- Finally, there are unknown knowns, which are things you think you know, but your knowledge is inaccurate. Rumsfeld used this in the context of false intelligence that led to the 2003 invasion of Iraq.

Don’t make decisions based on things you don’t know—even if you think you know it.

Subjects like FAA/FDA/MDR certification, Independent Verification & Validation, etc., are very specialized fields, and not everyone is an expert in them.

That’s okay, as long as you don’t bite off more than you can chew. It can be beneficial to bring in third parties that have the expertise and experience to accomplish the task you need. It might seem like an unnecessary expense at the time, but it will save you in the long run by preventing the need for constant reworks.

6) Don’t Lose Sight of Your Vision

You laid out a road map, defined an intended use, and have begun working on developing your prototype. Word is getting out about your product and you are being approached by other investors, resellers, etc., that all have different ideas for how your product can be used.

It can be great to serve multiple addressable markets with one product. However, it’s important to take things one step at a time and stick to your product roadmap.

Adding an extra feature here or there to make your product more appealing to a different market may sound like a good idea—until you realize that means you have to throw out all of your documentation and start from the ground up, further delaying your launch.

Those markets will still be there after you’ve launched your first generation product. Stick to your plan, achieve what you set out to accomplish, and expand when you have a successful and profitable product already deployed in the field.

General Digital Corporation specializes in custom product and software development in certified environments, as well as Independent Verification & Validation and documentation in line with FDA and FAA standards. For assistance with your product launch or other engineering requirements, contact me at jjherz@generaldigital.com or call us at 860.282.2900.