How Independent Verification & Validation Uncovers the Unknown

We we think about air travel today, we often associate it with flight delays, long security lines, and uncomfortable seats. However, in the early days of aviation, flying was considered more luxurious. Perhaps the first plane to provide this type of experience was the de Havilland Comet. The Comet was debuted by British Overseas Airways […]

Why ChatGPT Isn’t Replacing Humans Anytime Soon

If you read our last software blog, Challenges of Independent Verification & Validation of Intelligent Systems, you might have noticed that it seemed a little more…robotic than usual. That’s because we let ChatGPT write it for us. What is ChatGPT? ChatGPT is a new AI tool that allows users to basically talk to a robot. […]

Challenges of Independent Verification & Validation of Intelligent Systems

(This piece was written by ChatGPT. Learn more about this experiment here) Independent Verification and Validation (IV&V) is an important process for ensuring the safety and reliability of artificial intelligence (AI) and machine learning (ML) software systems that are used in safety-critical applications. These applications include self-driving cars, medical devices, military systems, and aviation systems, […]

Four Examples of SiMD IV&V Gone Wrong

When we go to a hospital or doctor’s office to be treated, we know that sometimes things might not go perfectly. Typically, we worry about the human elements. What happens if I don’t respond to the prescription my doctor gives me? What if a mistake during a routine surgery leaves me injured? However, one all-too-real […]

NVIS Display Selection Guide

Certain operating environments for ruggedized systems call for the need to be unseen. This is where Night Vision Imaging Systems (NVIS) come in. In simplest terms, these infrared-driven solutions allow operators to use their tactical equipment, without emitting significant light. As you could imagine, the most popular application is military. These systems are found in […]

Why You Want an Extended Warranty

General Digital’s ruggedized hardware solutions are built here in the United States with the highest-quality components and labor available. From workstations and display systems to keyboards, power supplies, and cables—you need to have confidence that your product is going to work when you need it to. However, despite taking every measure possible to avoid product […]

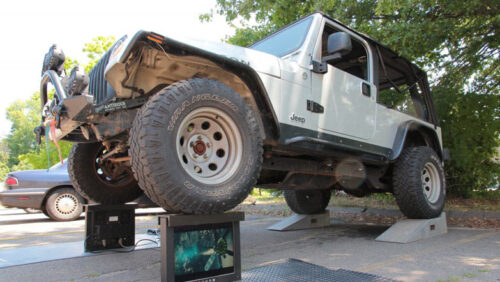

What are the True Costs of Saving when Purchasing Ruggedized Equipment?

Ruggedized electronics are found worldwide in many markets today: military, industrial, marine, mining and others. While they are all seeking the benefits of longevity and durability, each application tends to have its own set of requirements. Sometimes these specifications come with a higher price tag when compared to off the shelf solutions that appear to […]

The Next Generation of Video Control Technology for Ruggedized Systems

All computer systems rely on video controllers to process and deliver the signal that drives display. In some ways they go unnoticed, as they are often hidden inside the computer, suffering from “out of sight, out of mind” syndrome. But in reality, the importance of having a robust video controller can not be underestimated, especially […]

Improving Ruggedized System Performance with the Latest Connector Technology

Chances are, you’ve already come in contact with a USB-C connector. You might be surprised to learn that they were originally developed in 2014, but have only recently gained substantial traction. These connectors are now used in the latest laptops, phones, and tablets, and their incredible utility continues to flourish. General Digital is proud to […]

What does “Built to Meet MIL-STD” actually mean?

You can rest assured that just because a product might not be formally certified, if you bought it from General Digital, it’s gone through a rigorous, ISO 9001:2015 certified quality management process and can withstand the harshest environments on (or off) Earth.